CHLOROPUR: AUTONOMOUS CHLORINE PRODUCTION AND PROPORTIONNAL CHLORINATION

ChlorOpur® purifies the water and preserves health. It is the ideal solution to fight against waterborne diseases.

chloropur, is:

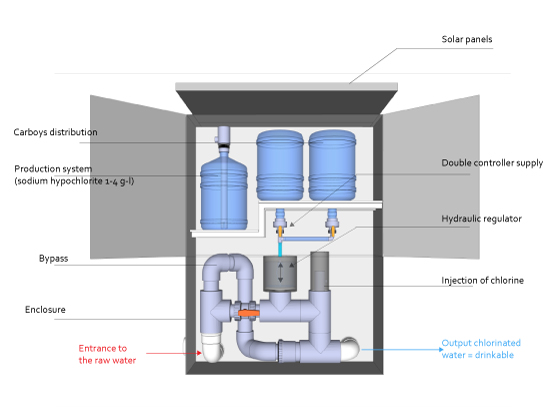

- The ChlorOpur® is a water purification tool that is placed upstream from the water tanks and consists of a chlorine production plant and a chlorinator.

-

It disinfects the raw water before it is stored in community tanks.

- Chlorine dosing is proportional to the flow of raw water. Furthermore, the device fits all types of water and all types of tanks.

- It works without energy, without piston metering and minimum supply pressure.

- Chlorinator accepts a wide range of dosage 500 to 10,000 l / h, with the ability to easily adapt to most important flows via a bypass system.

- The chlorinator works on the principle of communicating flasks.

- It is the height difference between the floater containing the disinfectant and the chlorine outlet point which determines the rate of the latter. The higher the raw water flow, the higher the flow of chlorine.

SAFETY AND ADAPTABILITY

Chlorination of water potability and security are controlled by the following parameters:-

Chloration rate:

amount of chlorine injected per volume of raw water at the chlorinator to ensure adequate chlorination.

- Residual chlorine:

remaining amount of chlorine in the water at the distribution point. This parameter, measured by colometry, associated with the contact time, is universally used to determine if water is safe or not from a bacteriological point of view.

To do this:

-

The chlorination rate can be changed through a micro control valve located at the chlorine injection point.

-

The chlorine concentration in carboys can be adapted by varying the duration of the electrolysis

PRODUCTION GENERAL PRINCIPLE OF CHLORINE

- The chlorOpur® electrolysis system produces sodium hypochlorite (bleach) at low concentration from a salt-water solution using an electrode and an electric current.

- This current is generated by the solar panel provided located on the chlorOpur® roof. Production is then independent from external energy sources and thus contributes the preservation of natural resources through the promotion of renewable energy.

- The Chloropur is an ideal alternative to conventional systems that use pellets (ex. HTH) involving logistical and / or financial issues for communities. The disinfectant is produced on site and only kitchen salt (NaCl) is required.

PRACTICALLY

-

Standard theoretical production capacity from 30 to 80 grams of chlorine per day, depending on the number of solar panels and sunlight.

-

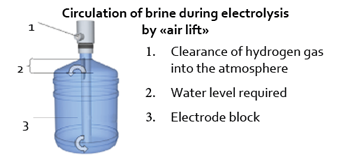

For the electrolysis, 750 g of sodium chloride are placed in a barrel of 30 liters of water to produce a brine of a concentration of about 25 g / l.

- The current generated by electrodes that are immersed in the brine causes the formation of active chlorine in the form of sodium hypochlorite, according to the following reaction:

- During the reaction, some hydrogen gas is produced contributing to the circulation of the brine in the carboy.

Altech s.a.f.s., rue Saint-Eloi, n°95 - 4300 Waremme (Belgique) - +32 (0).19.32.47.16 - altech.safs@gmail.com